The Campbell University School of Engineering’s shops support the hands-on curriculum with training in state-of-the-art tools in a safe environment.

All shops require instructor/lab manager/TA supervision and participation in the CAMEL Fab Safety and Training program.

CAMEL Fab

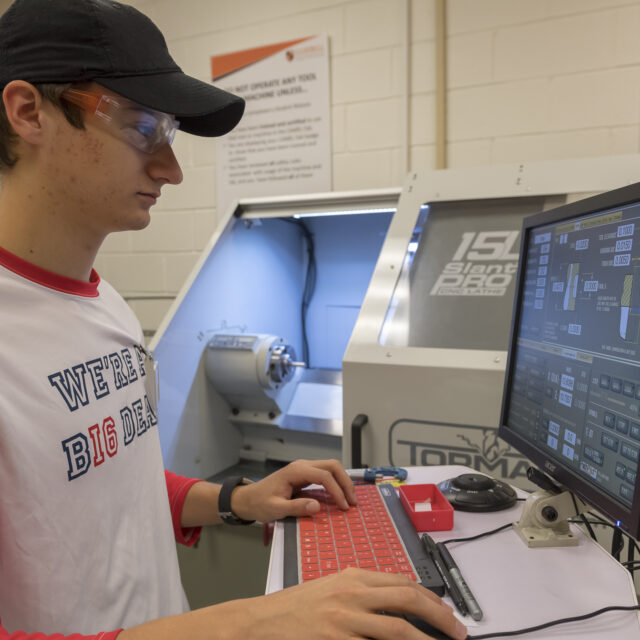

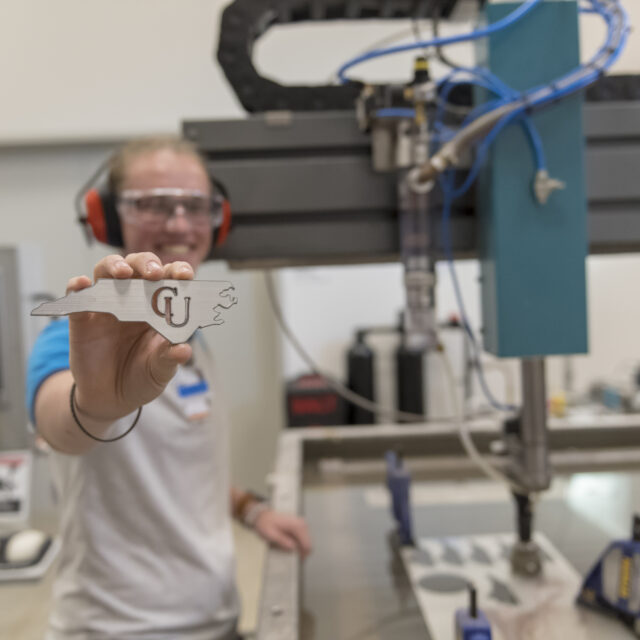

The Campbell Advanced Manufacturing Engineering Laboratory for Fabrication (CAMEL Fab) is located on the first floor of Carrie Rich Hall, this professional-grade metal and woodworking fabrication facility supports student projects from the freshman through the senior year. Capabilities include:

- CNC Milling Machine (Tormach PCNC 770)

- CNC Lathe (Tormach Slant Pro 15L)

- Manual Milling Machine (Wabeco F1200E)

- Manual Lathe (Wabeco D4000E)

- CNC Gantry Router (ShopBot)

- Laser cutter (Epsilon Fusion M2)

- Drill presses

- Band, miter, and table saws

- Sanding and grinding equipment

- Professional high-precision metrology (measurement) tools

- A large variety of hand tools and light power tools

CAMEL Fab 2

The CAMEL Fab 2 in the Engineering Annex houses larger manufacturing equipment for industrial-level fabrication needs that arise from Senior Design projects and the HERT team’s needs. Use of this equipment requires a conversation with either a professor or the lab manager where the students’ work plan is critically reviewed to ensure the desired product is achieved. This discussion also entails a process hazards analysis to cover safety issues that are present from using this non-standard equipment.

CAMEL Fab 2 includes:

- Milling Machine (Acer E-Mill 3VS-II)

- CNC Milling Machine (ProtoTrack TMC7)

- Engine Lathe (Acer 1746G)

- Carbon-Fiber 3D Printer (Markforged X7)

- Welding equipment and plasma cutter

- Bandsaw, drill press, hydraulic press, metal brake

- Hand and power tools

CFx

Human Exploration Rover Team Shop

Campbell Engineering students can participate in NASA’s Human Exploration Rover Challenge and have a build space adjacent to the Fab 2 for fabrication and testing.

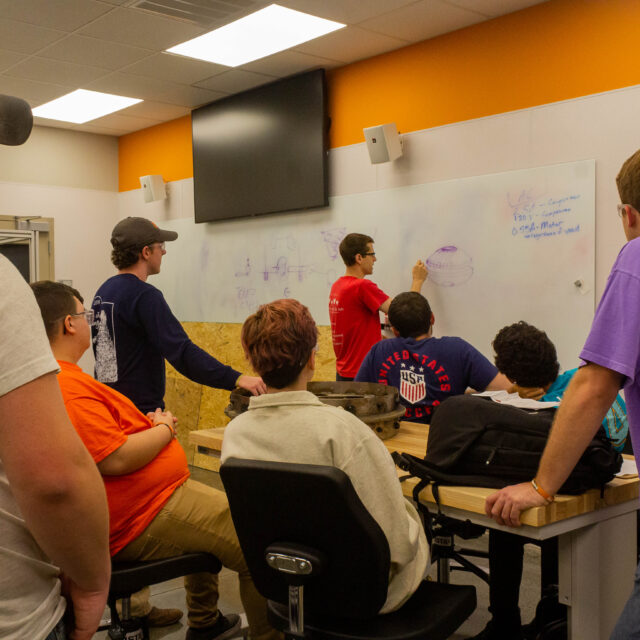

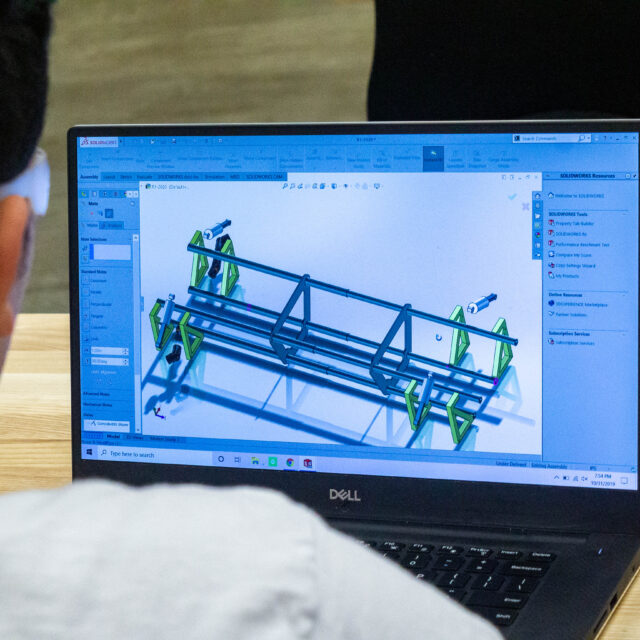

Senior Design

Seniors working on their year-long capstone design prototype have a dedicated space for work, collaboration and storage. It is stocked with common hand and power tools and adjacent to the Fab 2 for large scale machining.