To the School of Engineering lecture and lab are the same thing. Most classes are taught in “classlabs” with small class size fostering student-faculty interaction, hands-on learning, and deep understanding.

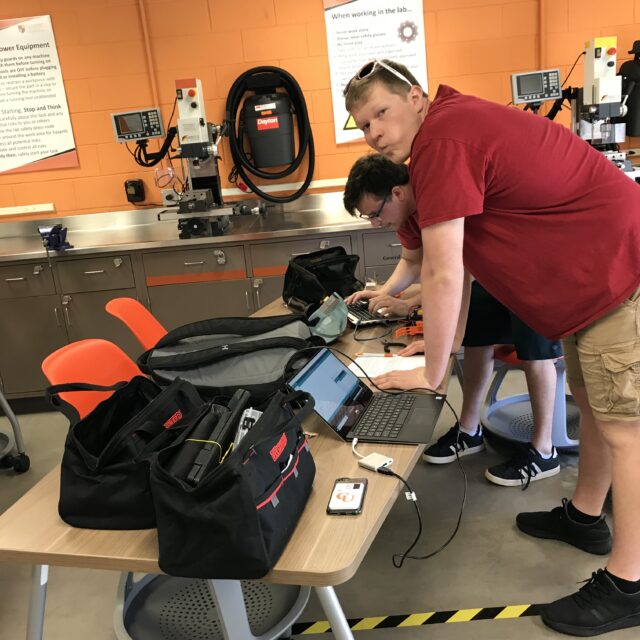

Area 87

Area 87 is a classlab in Room 387 of Carrie Rich Hall supporting instruction of ENGR 120 and 121 – Foundations of Engineering Design I & II. To facilitate this project-based, hands-on curriculum, Area 87 has student workstations with milling machines, hand tools, and electrical soldering. Here students learn the basics of design and fabrication, the foundation for their engineering education.

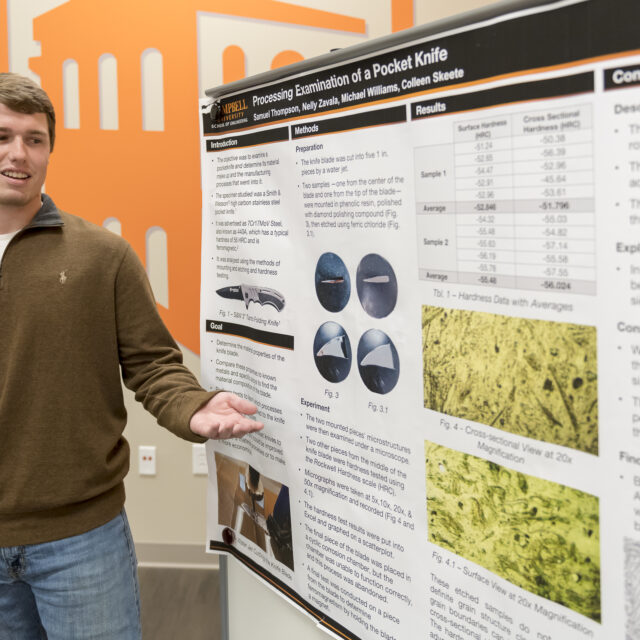

Materials Science Classlab

The Materials Classlab houses equipment used in the Materials Science and Processing and Statics and Strength of Materials courses. In this space, students use Tinius Olsen machines to twist, stretch, and bend material samples to their breaking points, furnaces to process metal and glass, and microscopes to understand the microstructure of materials after mounting, sanding, and etching the samples using the available equipment. Students work together to understand how different materials act and react from the micro to the macro scale to learn how to choose materials for engineering applications.

Chemical Operations Classlab

The Chemical Operations Classlab contains pilot plant scale chemical process equipment which enables students to complete labs and perform calculations that scale to full scale processes found in the real world. Students are able to observe processes such as distillation, falling film evaporation, open tubular column flow, packed column flow, gas absorption, batch reactions, continuous stirred tank reactions, and fluidized bed particle sizing/drying on a scale that is transferrable to large scale equipment used in chemical industry. This enables professors to create labs that are hands on and applicable to the petrochemical, pharmaceutical, consumer products, and specialty chemical industries.

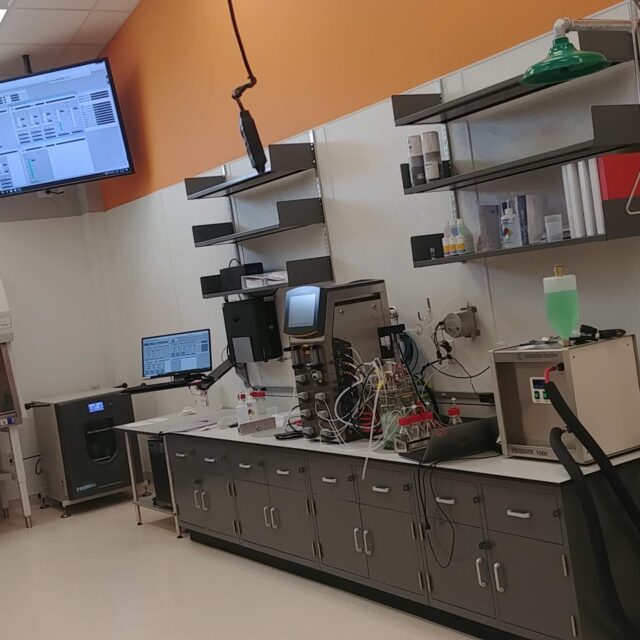

Bioprocessing Lab

The pharmaceutical emphasis of Campbell’s chemical/pharmaceutical engineering concentration is clearly seen in the Bioprocessing Lab in the Engineering Annex. In this state-of-the-art lab students will scale-up recombinant DNA expression from the benchtop to bioreactors.

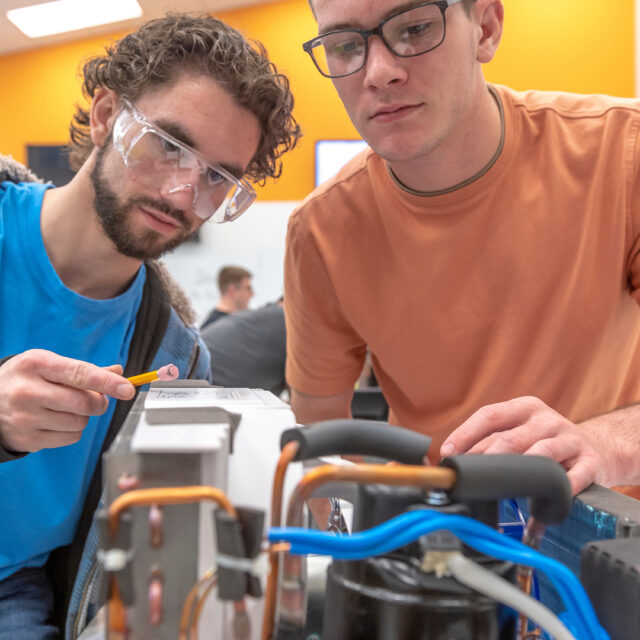

Energy Classlab

Equipment in the Energy Classlab focuses on measuring properties of liquids and gasses. Students will use Venturi meters, submersible pumps, pressure sensors, heat exchangers, and many other devices as they take courses such as Thermodynamics, Fluids, and Heat Transfer.

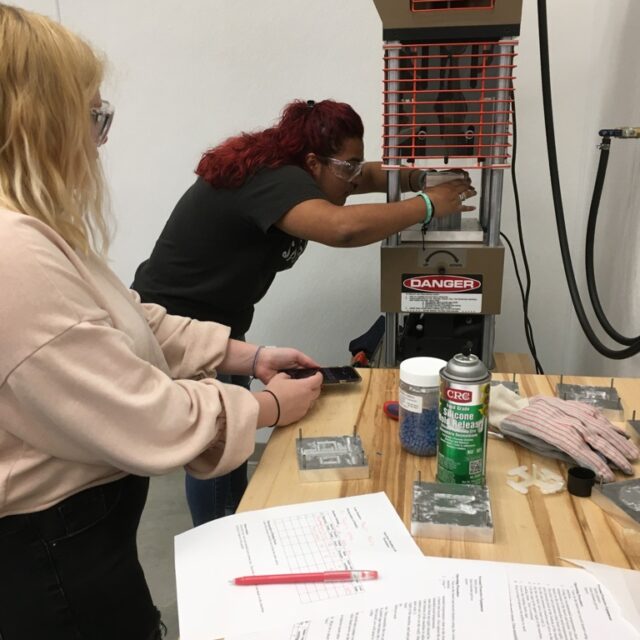

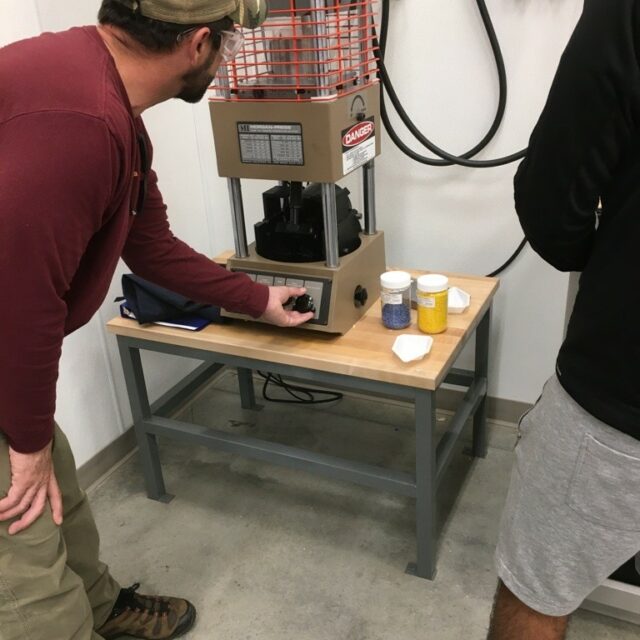

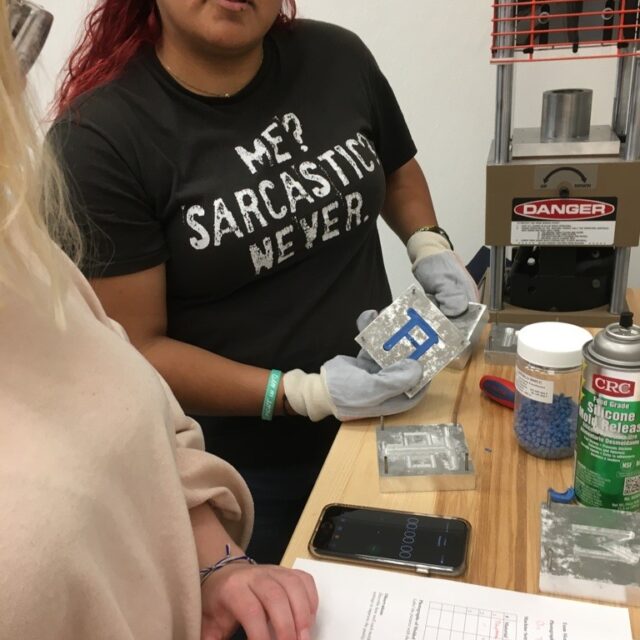

Manufacturing Classlab

The Manufacturing class-lab supports instruction in MECH 435 Manufacturing Engineering and MECH 480 Lean Manufacturing & Quality Engineering. Major equipment includes two 60,000 pound compression machines, injection molding machine, stylus profilometer, and dimensional measurement arm.

Electrical Engineering Classlab

Campbell’s electrical engineering concentration focuses on embedded systems, instrumentation, and control. In this state-of-the-art lab students design, build, and learn about electronics, embedded systems, sensors, motors, controls, communications, networks, and electromagnetic transmission.